Saturday, February 28, 2015

Cecil

Started a new project in butternut. I want something different than what I usually carve, so I start with a quick sketch. Then lay out the face proportions on the wood. I start removing wood to bring the nose out and begin to round over the top of his head. The piece of wood measures 12' x 10" x 4".

Friday, February 20, 2015

Mutton Chops

I carved this guy from an ugly cedar log. Just goes to show you never know what or who is hiding inside the wood. I started by roughing out the carving with a chainsaw. Then, I used mallet tools to block out the facial features, ears, neck and hair. I switch to hand tools and carve the eyes and detail the hair. Back to mallet tools to carve the shirt. I applied two coats of lacquer and will finish with a coat of wax in a few days.

Saturday, February 7, 2015

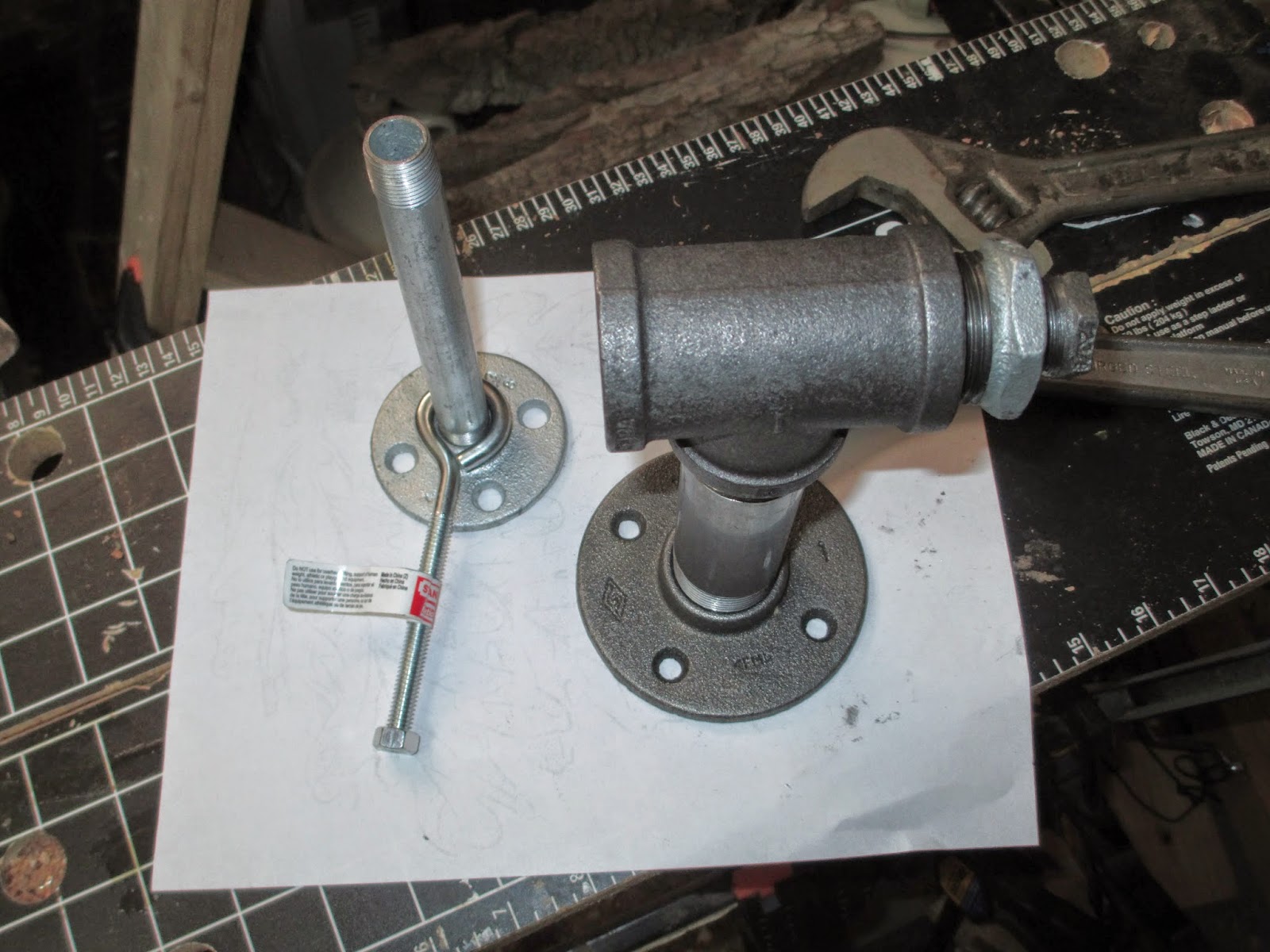

How To Build a Carving Vise

Last year I posted pictures of a carving vise. It was featured in Woodcarving Illustrated Magazine issue #5 from 1998. The article was written by Lynn Diel, and all credit goes to him. I only made one change to the vise to increase the gripping power when using it with large carvings. I received a lot of comments and questions about exactly how to build this vise. Hopefully this will help. I used black steel pipe and fittings except for the 3/8" pipe and flange, I could only find galvanized at the local hardware. Galvanized will cost you 30 - 40% more.

First a list of the parts needed -

1 - 1" pipe flange

1 - 4" or 6" length of 1" pipe (nipple)

1 - 1" pipe tee

1 - 1" to 1/2" pipe reducer

1 - 1/2" to 3/8" pipe reducer

1 - 3/8" pipe flange

1 - 6" length of 3/8" pipe (nipple)

1 - 5/16" eyebolt with washer and nut, 6" length

Approximate cost $30

Assembling the parts is pretty straight forward.

Here is the one change I made. If you are only going to use your vise for carving with hand tools you can bypass this step. But, if you want it to hold larger carvings and to use with mallet tools, this will prevent the vise from slipping. I made four notches on one end of the pipe tee with a hand grinder. This allows the 3/8" pipe that is holding the carving to set horizontal or vertical.

The black steel has an oily film.You need to clean the vise before applying a couple coats of good primer, and two coats of paint. If you used galvanized steel you can skip this step.

Secure your vise to a solid work surface, or to a board you can clamp to a bench or table. I attach the carving to the 3/8" pipe flange with drywall screws drove in at angle toward the center. If you like to work on more than one carving at a time, like me, buy an extra 3/8" pipe and flange. You can leave them attached and switch from one carving to another.

Happy Carving

First a list of the parts needed -

1 - 1" pipe flange

1 - 4" or 6" length of 1" pipe (nipple)

1 - 1" pipe tee

1 - 1" to 1/2" pipe reducer

1 - 1/2" to 3/8" pipe reducer

1 - 3/8" pipe flange

1 - 6" length of 3/8" pipe (nipple)

1 - 5/16" eyebolt with washer and nut, 6" length

Approximate cost $30

Assembling the parts is pretty straight forward.

Here is the one change I made. If you are only going to use your vise for carving with hand tools you can bypass this step. But, if you want it to hold larger carvings and to use with mallet tools, this will prevent the vise from slipping. I made four notches on one end of the pipe tee with a hand grinder. This allows the 3/8" pipe that is holding the carving to set horizontal or vertical.

The black steel has an oily film.You need to clean the vise before applying a couple coats of good primer, and two coats of paint. If you used galvanized steel you can skip this step.

Secure your vise to a solid work surface, or to a board you can clamp to a bench or table. I attach the carving to the 3/8" pipe flange with drywall screws drove in at angle toward the center. If you like to work on more than one carving at a time, like me, buy an extra 3/8" pipe and flange. You can leave them attached and switch from one carving to another.

Happy Carving

Friday, February 6, 2015

New Dust Collector

I finally broke down and bought a table top dust collector. I use a Foredom to rough out some of my smaller carvings, and it can really make a mess. This is a great new tool to help keep my work area clean and my lungs healthy. Should have bought one long ago.

Tree Troll

Subscribe to:

Posts (Atom)